A Device for Claming Shares to Landsides

Source: Submitted to the January 1896 edition of the Blacksmith and Wheelwright by A. M. Gore, Sayer, Kan

From A. M. Gore, Sawyer, Kan.

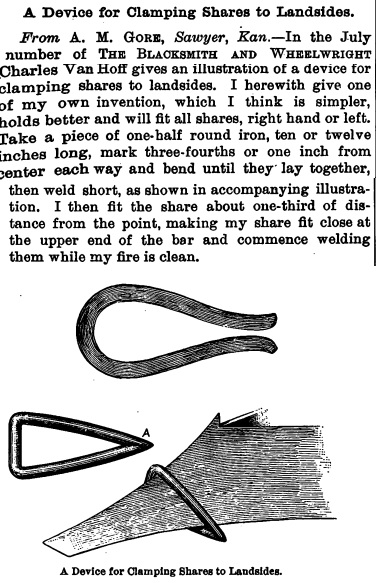

In the July number of The Blacksmith and Wheelwright Charles Van Hoff gives an illustration of a device for clamping shares to landsides. I herewith give one of my own invention, which I think is simpler, holds better and will fit all shares, right hand or left.

Take a piece of one-half round iron, ten or twelve inches long, mark three-fourths or one inch from center each way and bend until they lay together, then weld short, as showing in the accompanying illustration.

I then fit the share about one-third of distance from the point, making my share fit close at the upper end of the bar and commence welding them while my fire is clean.

I haven’t created one of these yet so consider the materials, tools, and procedure to be educated guesses.

Materials Needed:

- 10-12 inches of 1/2 inch round.

Procedure:

- Mark 3/4 or 1 inch from center on each side.

- Bend until the ends lay together

- Weld ends.

- Fit to share and weld to share.

If you need to clamp your share to a landside this seems like a reasonable option to do so. It’s not something I’ve run into but a great project for someone restoring old plows.

The most challenging part of this project is likely to be welding the clamp to the share which will involve heating and working with a large bit of steel.

The clamp idea seems to be a good one as J. L. Albow of I. T. notes in the same edition:

From J. L., Ablow, I. T. —

From J. L., Ablow, I. T. —

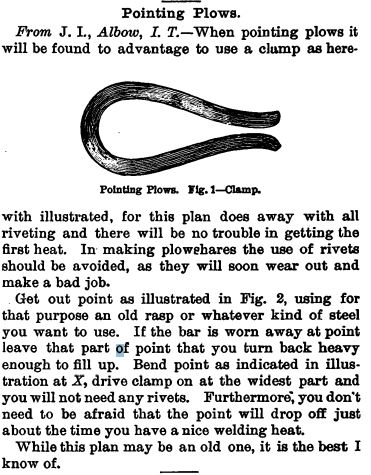

When pointing plows it will be found to advantage to use a clamp a

s herewith illustrated for this plan does away with all riveting and there will be no trouble in getting t

he first heat. In making plowshares the use of rivets

should be avoided, as they will soon wear out and make a bad job.

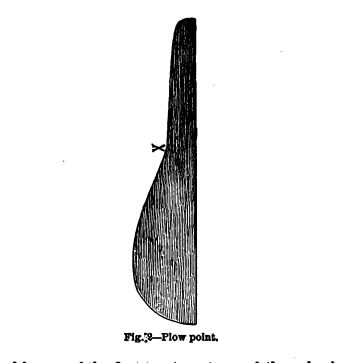

Get out point as illustrated in Fig 2, using for that purpose an old rasp or whatever kind of steel you want to use. If the bar is worn away at point leave that part of point that you turn back heavy enough to fill up. Bend point as indicated in illustration at X, drive clamp on at the widest part and you will not need any rivets. Furthermore, you don’t need to be afraid that the point will drop off just about the time you have a nice welding heat.

While this plan may be an old one, it is the best I know of.