Trenton Anvils

Overview

Trenton was one of the major anvil manufactures in the late 1800s through 1950. A new method of combining a cast base with a wrought upper body resulted in significantly cheaper anvil.

Due to the low cost Trenton anvils were sold under their own brand as well as numerous other brandings.

The best source of information on Trenton Anvils is the book Anvils In America which contains significantly more information on Trenton Anvils and their history than I have presented here.

Individual Anvils by Serial #

History of Trenton Anvils

The Trenton Anvil was produced from around 1878 until about 1952

- 1868 Incorporated Mar. 5 as Trenton Vise & Tool. Co by J. Howard Murray, Thomas S. Murray, and others. (1)

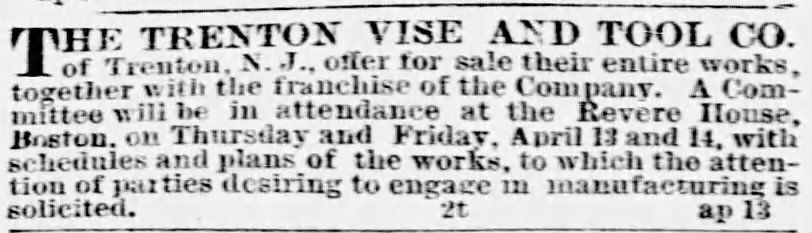

- 1871 April 14th – Attempt to sell the company

The Boston Evening Transcript notes “The Trenton Vise and Tool Co. of Trenton N.J. offer for sale their entire works together with the franchise of the Company. A committee will be in attendance at the Revere House, Boston, on Thursday and Friday, April 13 and 14, with schedules and plans of the works, to which the attention of parties desiring to engage in manufacturing is solicited. “

The Boston Evening Transcript notes “The Trenton Vise and Tool Co. of Trenton N.J. offer for sale their entire works together with the franchise of the Company. A committee will be in attendance at the Revere House, Boston, on Thursday and Friday, April 13 and 14, with schedules and plans of the works, to which the attention of parties desiring to engage in manufacturing is solicited. “

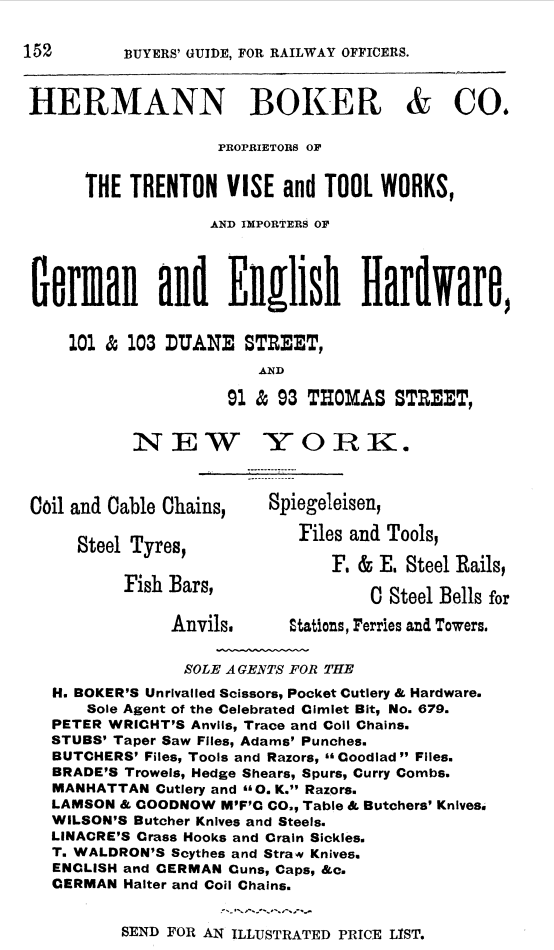

- 1873 Advertisements for Trenton Vise & Tool Works owned by Hermann Boker & Co. (2)

- 1874 April 23rd – First advertisement for Trenton Vise & Tool Works in Portuguese periodical O Novo Mundo (O New World)

- 1879 Sept 24th – Increasing iron prices and high demands for goods.

From 1879-1882 annual railroad construction quadrupled from 2,665 miles to 11,569 miles. This huge expansion in railroad construction was a major driver in an economic boom. The Cincinnati Enquirer reprinting an article from the New York Sun notes the increasing demand for iron and equipment. “In 1872 the price of iron was 4 cents and seven-tenths a pound. Five weeks ago it was only one and seven-tenths, and now it is two and seven-tenths, a price which again permits its importation… Various classes of iron goods were advanced 20 per cent… This was in sympathy with the advance in the price of iron at the mills.” A representative of Herman Boker & Co, owners of Trenton Vise & Tool Works, noted that few manufacturers, little stock, and high demand was leading to high workloads and slow delivery times. He notes that Trenton Vise & Tool Works will be working overtime for the next 3 months.

From 1879-1882 annual railroad construction quadrupled from 2,665 miles to 11,569 miles. This huge expansion in railroad construction was a major driver in an economic boom. The Cincinnati Enquirer reprinting an article from the New York Sun notes the increasing demand for iron and equipment. “In 1872 the price of iron was 4 cents and seven-tenths a pound. Five weeks ago it was only one and seven-tenths, and now it is two and seven-tenths, a price which again permits its importation… Various classes of iron goods were advanced 20 per cent… This was in sympathy with the advance in the price of iron at the mills.” A representative of Herman Boker & Co, owners of Trenton Vise & Tool Works, noted that few manufacturers, little stock, and high demand was leading to high workloads and slow delivery times. He notes that Trenton Vise & Tool Works will be working overtime for the next 3 months.

- 1881 – First advertisement with Trenton branded anvil shown published in a product catalogue for equipment manufactured by Ribon & March.(5)

- 1884 Oct 6th – Depression of 1882-1885 & Panic of 1884 Impacts Trenton Vise & Tool Company.

The Lancaster New Era notes that Trenton Vise and Tool works has reduced it’s working time to 8 hours a day. Also impacted in Trenton are the Trenton Iron Company, shut down, The American Saw Company, working 3/4 time, and Phoenix Iron Company, also working 8 hours per day.

The Lancaster New Era notes that Trenton Vise and Tool works has reduced it’s working time to 8 hours a day. Also impacted in Trenton are the Trenton Iron Company, shut down, The American Saw Company, working 3/4 time, and Phoenix Iron Company, also working 8 hours per day.

- 1890 ~Aug – Nov 10th – Trenton Vise and Tool works temporarily shuttered

For 14 weeks from roughly Aug to early November Trenton Vise and Tool works was out of operation and didn’t resume operations until a number of new capitalists added to the facilities of the company.

For 14 weeks from roughly Aug to early November Trenton Vise and Tool works was out of operation and didn’t resume operations until a number of new capitalists added to the facilities of the company.

- 1891 – Trenton Vise & Tool Works goes out of business.

- Some portion of business or assets sold to Van Wagoner & Williams Hardware Co.

- H Boker & Company seem to retain the Trenton copyright.

- H Boker became sales agent for Columbus Forge and Iron Company and probably recommended using the established Trenton brand for anvils.

- 1891 Dec 2nd – The Iron Age Nov 26th 1891 pg 56 – Auction Sale of Machinery and Tools of the Trenton Vise & Tool Company

- 5 Engine Lathes

- 2 Speed Lathes

- 2 Planer

- 2 Drills

- 1 Milling Machine, 2 heads

- 1 Milling Machine Hewes & Phillips

- 2 Bolt Cutters

- 1 Tapping Machine

- 6 Trip Hammers

- 4 Drop Hammers, Merrill pattern

- 1 Drop Hammer, Chesney pattern

- 1 Sheet Metal Drop

- 1 Parker Punch

- 1 Geared Punch

- 3 Blowers

- 70 lots of sundry small Tools

- 1891 – Dec 21st – A Hegria of Workmen

- They Leave Trenton, N.J., for Positions at Cleveland.

- A special car containing 20 mechanics was attached to the Ft. Wayne express westbound this morning. They were employees of the Trenton Vise and Tool Works, of Trenton, N. J., and were in charge of Edwin S. Mitchell, ex-chief of the fire department of Trenton.

- The men had their kits of tools and trunks of clothing with them and are going to Cleveland, O. Their firm has closed business in Trenton and has consolidated with the Van Wagner & Williams Machine works at Cleveland. About 300 men will be employed under the consolidation.

- “We are going on to work,” said Mr. Mitchell, “and will return to Trenton in the spring for our famillies. About 80 of the men will secure other employment. These I have with me are the most expert men we had. We left Trenton owing to a lack of facilities for shipping our products by rail. Everything had to be hauled. At Cleveland we will have better railway facilities, and, besides the largest part of our trade comes from the west, and we will be nearer to it. We think we will like the new location.”

- 1894 October 10th – In “The Latest Catalogues” section of Devoted to the American Hardware Trade · Volume 10 notes that The Van Wagoner & Williams people have succeeded in business. (4)

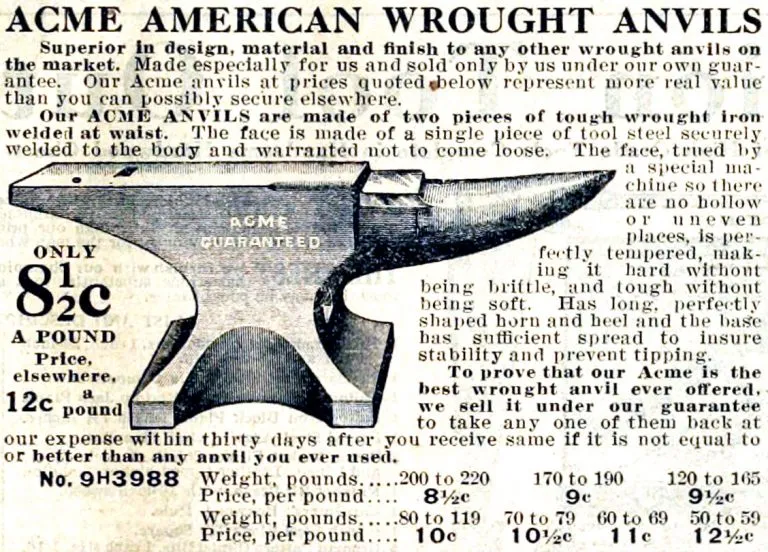

- 1880s-1890s – Anvils selling for 10-12 cents per pound. (6)

1890s David Buel starts to develop a new way of manufacturing anvils and attracting investors for an anvil company.

1890s David Buel starts to develop a new way of manufacturing anvils and attracting investors for an anvil company.

- Base cast of weldable steel (low carbon)

- Body Wrought Iron

- Face (Swedish Steel)

- 16 different base sizes made to fit a range of standard size anvils

- #23 base (21lbs) – 45-50lb anvil

- #41 vase (75lbs) – 170-200lbs

- #72 base – 600lb anvils

- Sometimes can find anvils with mis-sized bases. More common on early anvils.

- Can cause anvils to break at the waist. These are easy to repair though and can just be welded back together.

- 1899 October new anvil exhibited in Pittsburgh.

- 1898 January 25th – David Buel forms the Columbus Forge and Iron Company.

- 1898 Dec 17th – David Buel applied for patent on a new way of manufacturing anvils.

- Patent granted on Aug 8th 1899 – Full patent on Google Patents

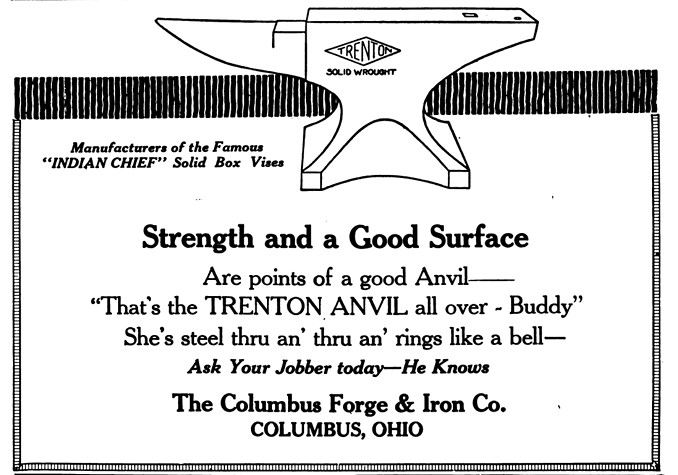

- 1900 September – First Columbus Forge and Iron Co. ad in The Blacksmith and Wheelwright

- 1901 March – The Blacksmith and Wheelwright advertised the Columbus Forge & Iron Co “Trenton” anvil.

- 1902 July 21st – Hiring forge men

- 1903 American wrought anvils selling for 7 1/2 cents per pound. Sears Roebuck offered one as low as 7 1/4 cents per pound.

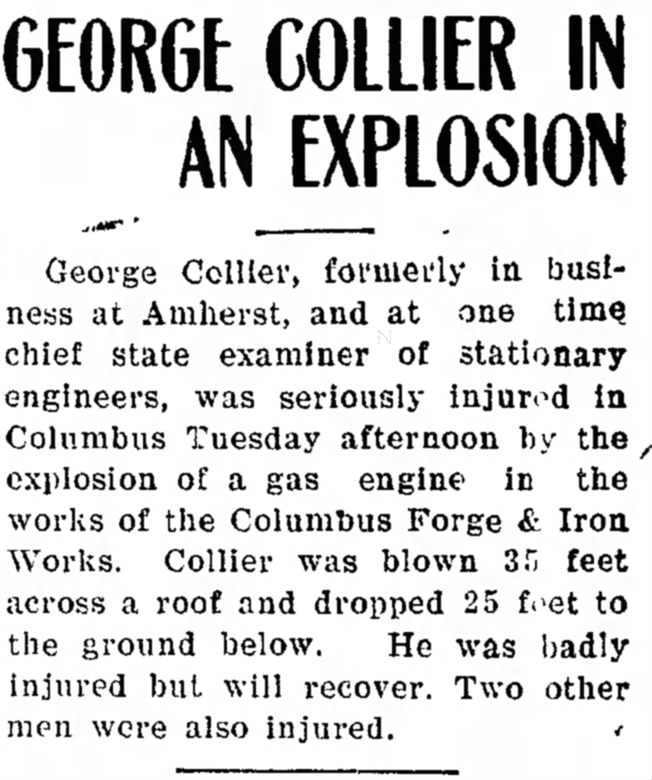

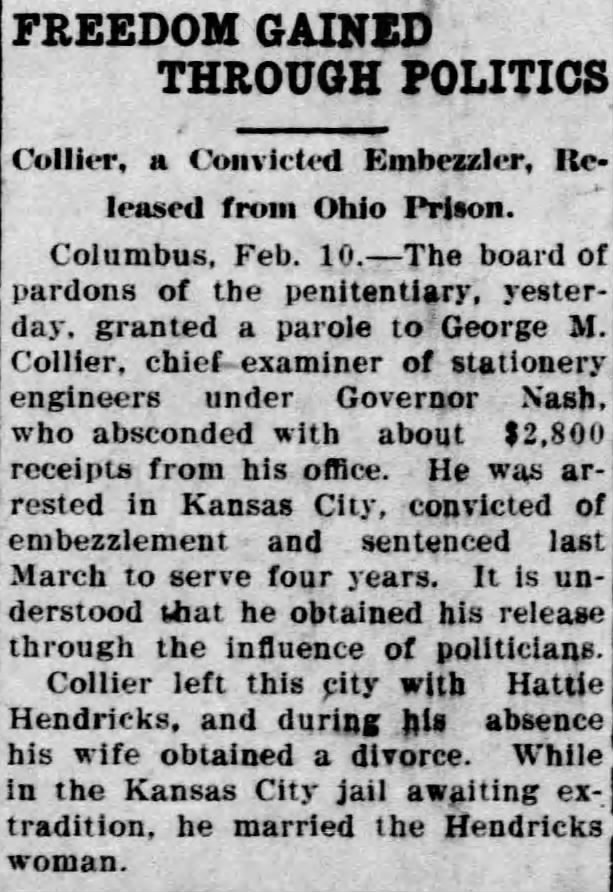

- 1906 July 11th – Three injured in explosion at Columbus Forge and Iron works

George M. Collier, was blown 35 feet across a roof, dropping 25 feet to the ground below, in an explosion of a steam pipe at the Columbus Forge and Iron works. Two other men were also injured.

George M. Collier, was blown 35 feet across a roof, dropping 25 feet to the ground below, in an explosion of a steam pipe at the Columbus Forge and Iron works. Two other men were also injured.- George M. Collier was a convicted embezzler who had been released on Feb 10th 1906 after absconding

with about $2,800 in receipts from his role as the state examiner of stationary engineers. He fled to Kansas City with Hattie Hendricks leaving his wife behind who divorced him during his absence a. He was sentenced to 4 years in prison and sent to prison on March 25th 1905 where he married Hendricks while in prison. During his parole it was “explained that he had made some improvements in the heating apparatus at the prison. A tip for embezzlers to learn useful trades. Perhaps a scientist could earn his freedom in a week or two.” (8)

with about $2,800 in receipts from his role as the state examiner of stationary engineers. He fled to Kansas City with Hattie Hendricks leaving his wife behind who divorced him during his absence a. He was sentenced to 4 years in prison and sent to prison on March 25th 1905 where he married Hendricks while in prison. During his parole it was “explained that he had made some improvements in the heating apparatus at the prison. A tip for embezzlers to learn useful trades. Perhaps a scientist could earn his freedom in a week or two.” (8)

- 1920 – Columbus Forge and Iron Co and produced 176,609 serial-numbered Trenton anvils

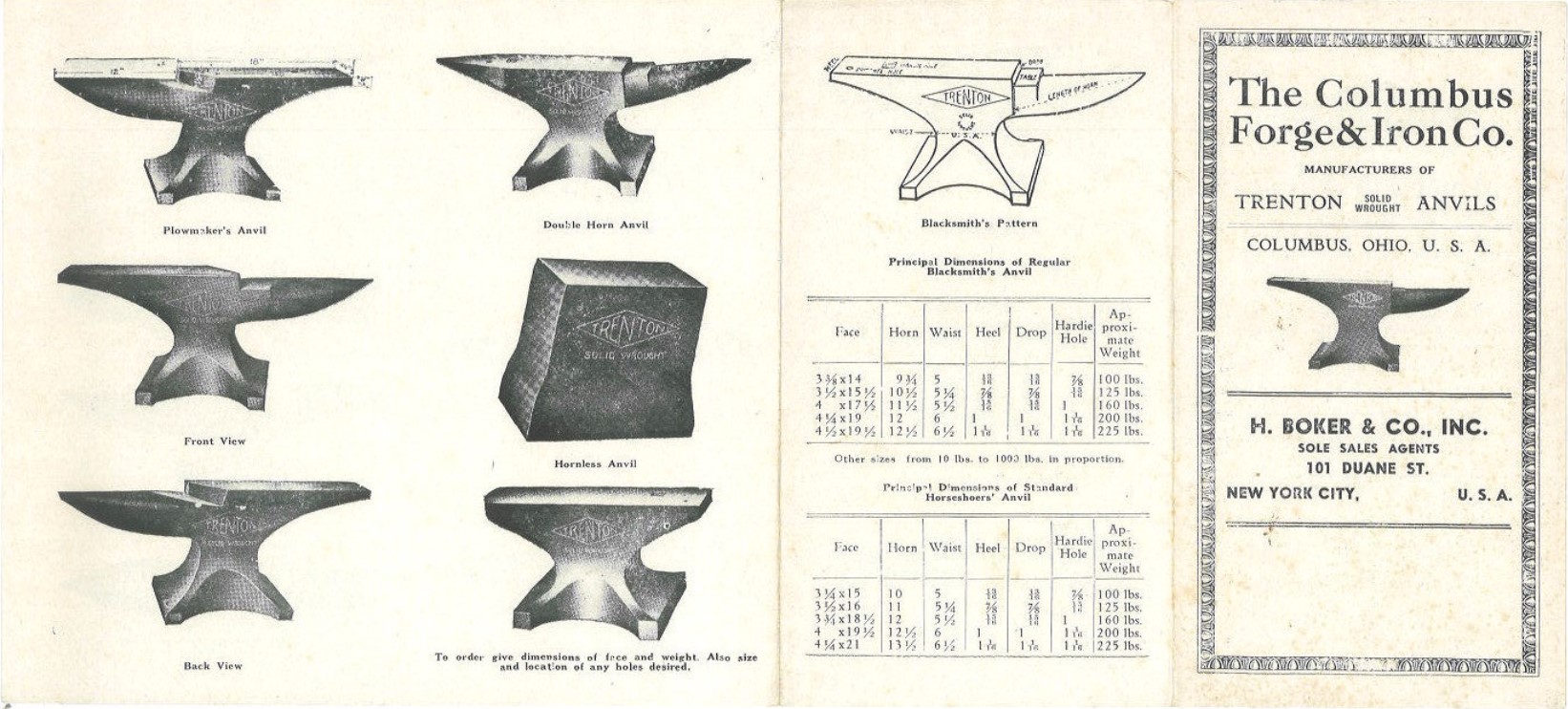

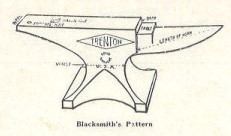

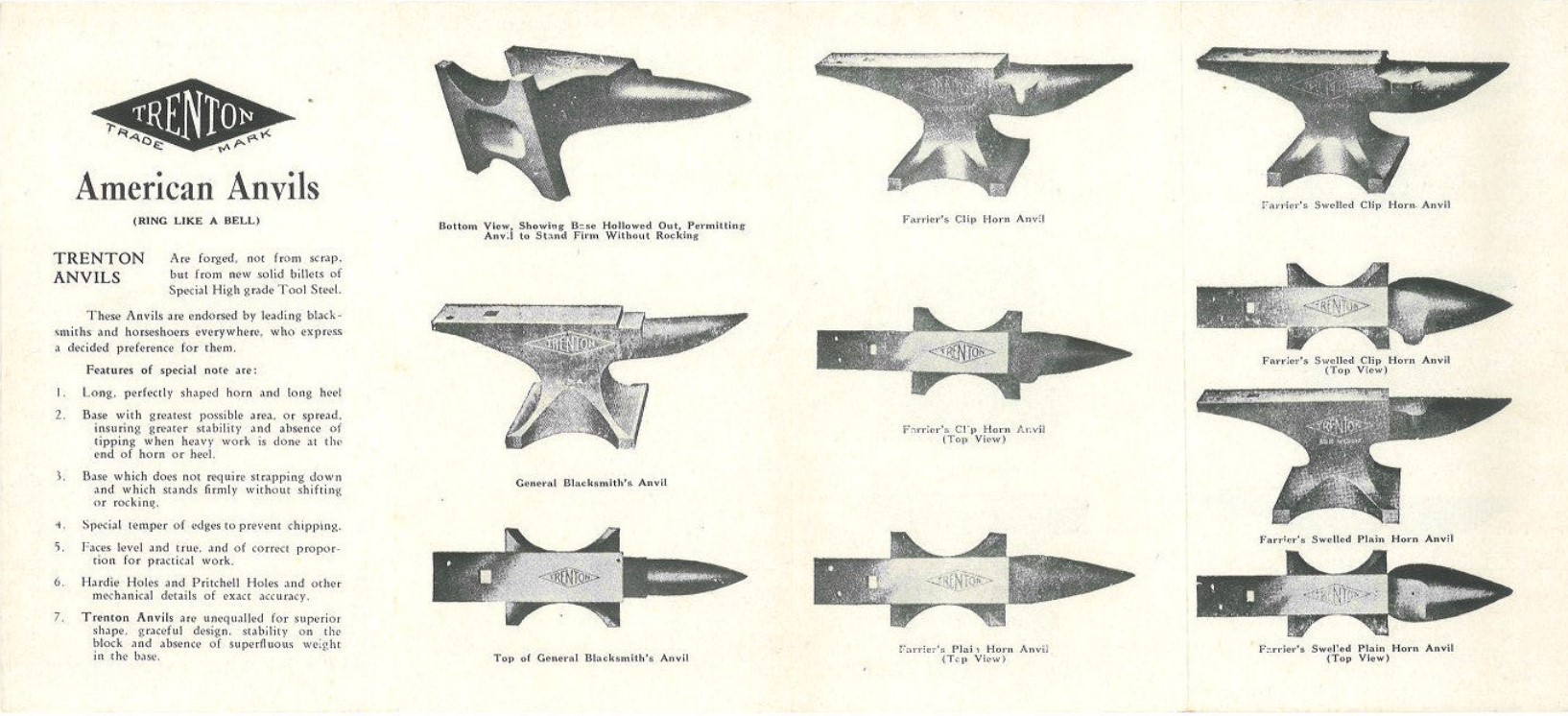

- Likely 1920s-1930s – Trenton Brochure

- This brochure is from James Bowers who received it and a mini Trenton anvil (see below) as gifts when Jim worked with Columbus Forge and Iron Co. to convert a furnace from straight gas firing to gas or oil firing firing. Jim suspects the brochure is pre-WW2.

- In it we can see that Trenton made a number of types of anvils including:

- Plowermaker’s Anvil

- Double Horn Anvil

- Hornless Anvil (2 varieties, one looks like a saw makers anvil while the other has double heels)

- General Blacksmith’s Anvil

- Farrier’s Clip Horn Anvil

- Farrier’s Swelled Clip Horn Anvil

Principal Dimensions of Regular Blacksmith’s Anvil

| Face | Horn | Waist | Heel | Drop | Hardie Hole | Approximate Weight |

|---|---|---|---|---|---|---|

| 3 3/8 x 14 | 9 ¾ | 5 | 13/16 | 13/16 | 7/8 | 100 lbs. |

| 3 ½ x 15 ½ | 10 ½ | 5 ¼ | 7/8 | 7/8 | 15/16 | 125 lbs. |

| 4 x 17 ½ | 11 ½ | 5 ½ | 15/16 | 15/16 | 1 | 160 lbs. |

| 4 ¼ x 19 | 12 | 6 | 1 | 1 | 1 1/16 | 200 lbs. |

| 4 ½ x 19 ½ | 12 ½ | 6 ½ | 1 1/16 | 1 1/16 | 1 1/16 | 225 lbs. |

Other Sizes from 10lbs. to 1000lbs in proportion.

Principal Dimensions of Standard Horseshoers’ Anvil

| Face | Horn | Waist | Heel | Drop | Hardie Hole | Approximate Weight |

|---|---|---|---|---|---|---|

| 3 ¼ x 15 | 10 | 5 | 13/16 | 13/16 | 7/8 | 100 lbs. |

| 3 ½ x 16 | 11 | 5 ¼ | 7/8 | 7/8 | 15/16 | 125 lbs. |

| 3 ¾ x 18 ½ | 12 | 5 ½ | 15/16 | 15/16 | 1 | 160 lbs. |

| 4 x 19 ½ | 12 ½ | 6 | 1 | 1 | 1 1/16 | 200 lbs. |

| 4 ¼ x 21 | 13 ½ | 6 ½ | 1 1/16 | 1 1/16 | 1 1/16 | 225 lbs. |

- 1939-1945 – WWII US Army Air Force bought a number of 25lb anvils for use on B24 Liberator bombers. It is unclear why.

- Many other anvils sold for shoeing army mules.

1946 number of freight carloads of Trenton anvils shipped to Russia.

1946 number of freight carloads of Trenton anvils shipped to Russia.

- ~1952 stopped producing anvils.

- Produced another 48,952 from 1920-1952 anvils for a total of ~225,000

- Continued as a forging shop

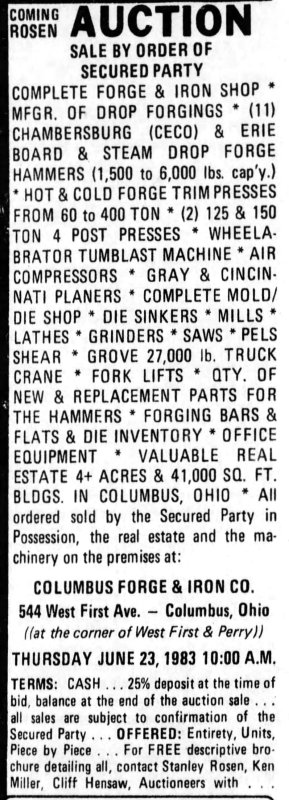

- 1982 June – Out of business.

- 1983 June 5th – Auction of Columbus Forge & Iron Co. remaining equipment

Resources

-

- Acts of the Legislature of the State of New Jersey (1868) – pg 241-243

- Buyers’ Guide and Mechanics’ Manual For the Use of Railway Officials, Containing a Complete List of All Articles Wanted by Railway Companies, with the Names of Exclusive First Hands, Among Manufacturers, Importers and Commission Merchants in Every Line; Also, a Number of … Tables and Recipes … 1873 – pg 152

- O Novo Mundo Volume Quarto 1873-1874 April 23rd 1874 pg 135

- Hardware – Devoted to the American Hardware Trade · Volume 10 pg 34

- Illustrated Catalogue of Machinery Manufactured by Ribon & March 1881 pg 103

- Anvils in America, Richard Postman

- The Pittsburgh Press – Dec 21 1891 – Pg 1

- The Daily Sentinel-Tribune Feb 17th 1906 pg 1 & 5 “Parole Matters”

Trenton ANvil Dating

Serial Number & Production Year

Individual Anvils by Serial #

| Serial Number | Date | Anvils Produced | Serial Number | Date | Anvils Produced |

|---|---|---|---|---|---|

| Unmarked | <1898 |

4,000 |

179713-183238 | 1922 | 3525 |

| 0-4000 | 1898* | 7,999 | 183239-186528 | 1923 | 3289 |

| 4001-12000 | 1899* | 7,999 | 186529-188290 | 1924 | 1761 |

| 12001-20000 | 1900* | 5,999 | 188291-191738 | 1925 | 3447 |

| 20001-26000 | 1901* | 7,999 | 191739-194975 | 1926 | 3236 |

| 26001-34000 | 1902* | 7,999 | 194976-195355 | 1927 | 379 |

| 34001-42000 | 1903* | 7,999 | 195356-196467 | 1928 | 1111 |

| 42001-50000 | 1904* | 7,999 | 196468-197444 | 1929 | 976 |

| 50001-58000 | 1905* | 7,999 | 197445-198190 | 1930 | 745 |

| 58001-66000 | 1906* | 7,999 | 198191-200199 | 1931-1935 | 2008 |

| 66001-74000 | 1907* | 7,999 | 200200-201638 | 1936-1938 | 1438 |

| 74001-82000 | 1908* | 7,999 | 201639-202429 | 1939-1940 – WW2 | 790 |

| 82001-90000 | 1909* | 7,999 | 202430-210375 | 1941-1943 – WW2 – US enters | 7945 |

| 90001-98000 | 1910* | 7,999 | 210376-216185 | 1943-April 1945 – WW2 | 5809 |

| 98001-106000 | 1911* | 7,999 | 216186-221625 | April 1945-Feb or Mar 1947 – WW2 ends Sept 1945 | 5439 |

| 106001-114000 | 1912* | 7,999 | 221626-222501 | Feb/Mar 1947-Mar 1948 | 875 |

| 114001-122000 | 1913* | 7,999 | 222502-223202 | March 1948-Dec 1948 | 700 |

| 122001-130000 | 1914* – WW1 | 7,999 | 223203-223867 | Dec 1948-Oct 1949 | 664 |

| 130001-138000 | 1915* – WW1 | 7,999 | 223868-224057 | Oct 1949 – July 1950 | 189 |

| 138001-146000 | 1916* – WW1 | 7,999 | 224058-224465 | July 1950 – July 1951 | 407 |

| 146001-158000 | 1917* – WW1 US enters | 11,999 | 224466-224838 | July 1951 – March 1952 | 372 |

| 158001-170000 | 1918* – WW1 | 11,999 | 224839-225551 | March 1952 – June 1953? | 712 |

| 170001-176000 | 1919* | 5,999 | Total Produced | 225,506 | |

| 176001-178436 | 1920 | 2435 | |||

| 178437-179712 | 1921 | 1275 |

*Pre1920s ranges may be 1-2 years off as detailed records for those years were lost.

Identification Guide

-

Pre-1898 –

- Trenton Logo no serial number on front right foot.

- Weight on side not front left foot.

- Flat under base.

- Base is forged.

-

1898

- Serial Number on front left foot.

- USA under trademark

- May have stepped foot

- 4 handling holes

- Flat under base.

- Forged base.

-

Very Soon After 1898

- Cast base – casting line line may be seen (very large anvils may have forged base), Sharp feet on base.

- Hourglass shaped depression under base.

- Weight on Side not front.

-

1890

- Weight on front right foot.

-

1899

- Example logo from 1899

-

1904-1907

- No handling hole in front of the foot

- One, two or three other handling holes still present based on size.

-

1907

- Handling hole only in waist under horn

- Hourglass depression starts to be replaced with depressed oval.

-

1909

- All handling holes gone (except very large anvils which may or may not have one)

-

1910

- Oval Base exclusively

-

1920s

- Cast feet on base around rounded not sharp.

-

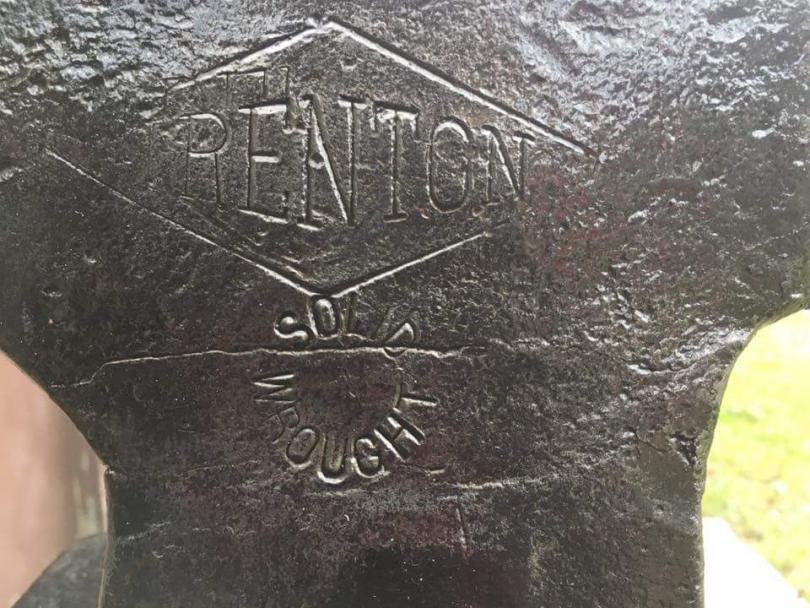

1927

- Upper body becomes solid-forged tool-steel top with electric weld to base.

- Diamond around Trenton becomes dashed lines, Trenton lettering curved rather than straight.

-

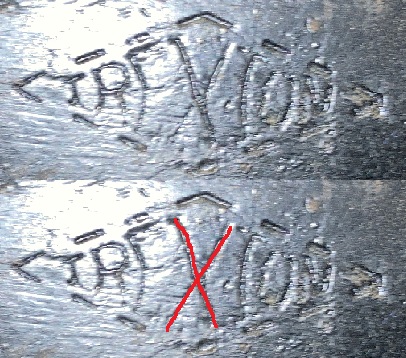

Late 1930s

- N in Trenton is styled to look like an X

Trenton – Unusual Anvils

CFI Mini Anvil

James Bowers who worked as an engineer/salesman for Pyronics Inc in the mid 1970s making natural gas and oil burners for industrial furnaces.

Jim worked with Columbus Forge and Iron Co. to convert a furnace from straight gas firing to gas or oil firing firing in case there was high demand and the Columbia Gas Company curtailed their industrial customers. By the time Jim worked with them they had stopped producing anvils (in 1953) but he was given several gifts including a mini anvil that he thinks was to celebrate their anniversary.

The anvil is a small closed die forging anvil with the CFI logo on one side and the name and founding year, 1898, on the other.

These small anvils are not stamped with a weight or serial number. It is currently unknown how many of them were made.

They weigh 1lb 5oz

Trenton – Other Trademarks

Because of the price point for Trenton anvils they were sold under a wide variety of other brands. As I find evidence for rebranded Trenton Anvils they will be added to the list.

Note that the Lowest and Highest Serial numbers are based on anvils I have found photographic evidence of and added to my list or are listed in Anvils In America. It is likely, especially early in this process that the range will be very inaccurate.

Individual Anvils by Serial #

| Trademark / Low / High Serial # | Advertisement | Example | Comments |

|---|---|---|---|

| Acme

66690 / 146955 |

|

|

Acme was the trademark for the Sears & Roebuck anvils. |

| Ajax

49094 |

Likely branding for J.H. Ashdown Hardware. Saskatoon Sessional Papers lists the purchase of a 164lb Ajax anvil from J.H. Hardware Co. in 1916-1917.

Also sold rebranded Hay Budden Anvils: Example Hay Budden with Ajax Branding |

||

| A T C, USA

124449 |

|||

| Black Prince

192770 |

Shapleight Hardware Company, St. Louis MO.

Over 300 in 1920/1930 |

||

| Buel Patent

10718 |

|

|

Early Columbus Forge and Iron Company Trademark |

| CFI

314?4 / 113355 |

Columbus Forge and Ironworks Trademark | ||

| Cole

69039 |

|||

| Derby

15931 / 24712 |

|||

| Indian Chief

81940 |

Example on I Forge Iron | Columbus Forge and Ironworks Trademark | |

| Lakeside

183427 |

Montgomery Ward trademark | ||

| Phoenix

47254 |

|||

| Reliable

61275 |

|||

| Roberts Anvil

1029 / 13726 |

|

||

| Village Forge |  |

Hundreds made in 1920s-1930s | |

| Vulcan

8072 |